-

空间辐射环境中的高能粒子,如重离子、质子等,射入器件的敏感区,极易诱发单粒子效应(Single Event Effect, SEE),造成器件及电路出现错误、失效或故障。随着器件特征尺寸的不断缩减,SEE中的单粒子瞬态(Single Event Transient, SET)已成为空间辐射环境中集成电路可靠性的主要威胁之一[1-4]。

技术节点进入纳米尺度后,涌现出了许多新结构、新材料、新工艺的器件,如鳍式场效应晶体管(Fin Field-Effect Transistor, FinFET)器件,一种非平面结构的器件,有效抑制了短沟道效应,改善了器件的电学性能 [1-2, 5-6]。碳化硅(SiC)作为第三代半导体材料,具有高击穿电场、高载流子饱和漂移速度和高热导率等优点[7-8]。深入分析新结构、新材料的SEE效应机理,是开展抗辐射加固设计的基础和前提。针对SiC金属-氧化物半导体场效应晶体管(Metal-Oxide-Semiconductor Field-Effect Transistor, MOSFET)器件的SEE,特别是单粒子栅穿(Single Event Gate Rupture, SEGR)和单粒子烧毁(Single Event Burnout, SEB),开展了大量工作[7-13]。研究结果表明,SiC材料的抗SEB能力优于Si材料,而两者的抗SEGR能力相当。实验表明,低电压时,SiC MOSFET器件内部会产生永久损伤,引起漏电流增加,甚至烧毁,器件的抗单粒子能力较弱[13]。Zhang等[9]发现SiC MOSFET器件外延层的电场强度越大,重离子受电场作用偏向电场方向运动的可能性越大,形成的能量沉积更多、更集中。然而,针对SiC MOSFET器件的单粒子瞬态效应研究的文献偏少。Lu 等 [10]研究了重离子撞击SiC功率MOSFET器件后的瞬态响应机理。Shangguan [14]利用激光脉冲开展了SiC MOSFET的SET试验研究,分析了不同激光能量、不同工作电压下的SET脉冲。结果表明,工作电压增大及激光能量增加,导致器件发生SET的敏感位置增加,SET峰值接近。然而,与MOSFET结构截然不同的FinFET结构和SiC材料结合,构成新型器件。针对这种新器件,开展其SET效应研究,对抗辐射加固设计工作具有重要的理论意义。我们前期对4H-SiC FinFET器件的SET进行的分析研究表明,SiC材料对SET的免疫性更强[11]。之所以SiC的器件抗单粒子效应的能力比Si的强,是因为SiC的禁带宽度比Si的高2~3倍,使得产生一个电子空穴对所需的能量更高[12]。同时,环境温度会对器件的许多参数产生影响,如载流子迁移率、碰撞电离率、双极放大系数等[15-16]。研究表明,与传统MOSFET的温度效应不同,体硅FinFET器件的抗SET性能随着温度的升高呈增加趋势[17]。此外,由技术节点缩减导致的工作电压降低,也对SET的电荷收集过程产生影响[18-19]。因此,开展温度和偏压对SiC FinFET器件的SET的影响机理研究,对集成电路设计和抗辐射加固研究,具有非常重要的理论意义和应用价值。

-

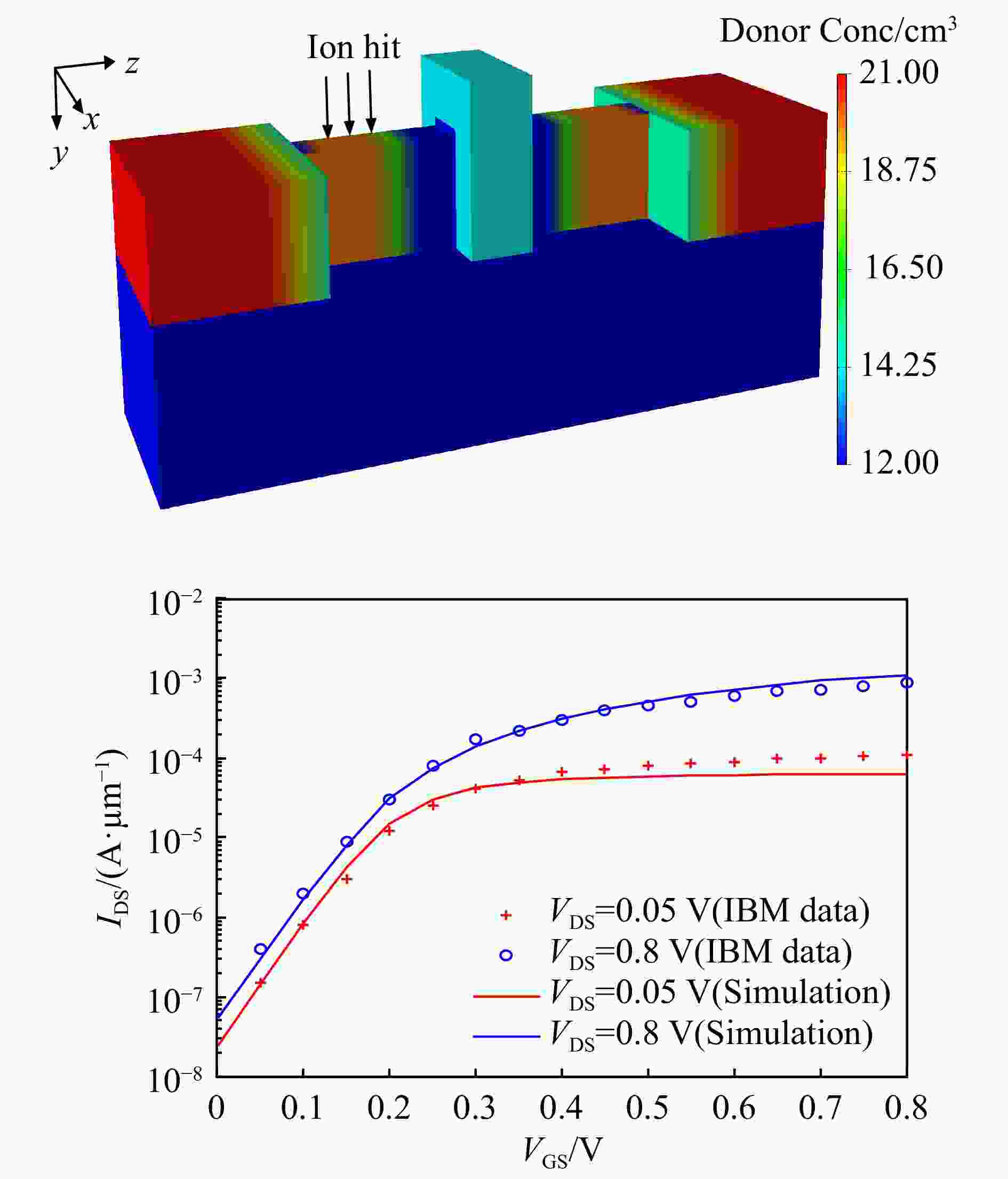

基于TCAD [16]构建14 nm 绝缘体上硅(Silicon-On-Insulator, SOI) FinFET器件的SET仿真模型 [6, 11]。采用高k栅介质(HfO2)和金属栅(TiN)结构,并对Si材料器件的电学性能进行试验校准[20],结果如图1所示。在此模型基础上,设置4H-SiC材料参数[11],如表1所列。器件其他参数[6, 11]为:栅长14 nm,fin高18 nm,fin宽10 nm,等效氧化层厚度0.5 nm,S/D长度35 nm,S/D扩展区长度33 nm,沟道均匀掺杂浓度5×1015 cm−3,源/漏高斯掺杂浓度1×1021 cm−3,源/漏扩展区高斯掺杂浓度8×1019 cm−3,衬底均匀掺杂浓度1×1015 cm−3。使用的物理模型包括:与掺杂浓度和高k栅介质相关的迁移率退化模型、飞利浦标准化迁移率模型、高电场饱和模型、能带隙和电子亲和性模型、BQP(Bohm Quantum Potential)模型、SRH(Shockley-Read-Hall)和Auger重组模型、费米统计模型及重离子辐射模型等 [6, 11]。

仿真参数 数值 仿真参数 数值 禁带宽度 3.2 eV 相对电介质常数 9.7 电子迁移率(300 K) 900 cm2/(V·s) 饱和电子迁移率 2×107 cm/s -

高能粒子在4 ps时延后,垂直射入器件源栅中间的fin敏感区,如图1(a)所示,粒子的特征半径为10 nm、特征时间为0.5 ps,线性电荷淀积(Linear Charge Deposit, LCD)为0.05 pC/μm,环境温度为300 K,偏压为0.8 V,仿真运行时间1 ns。

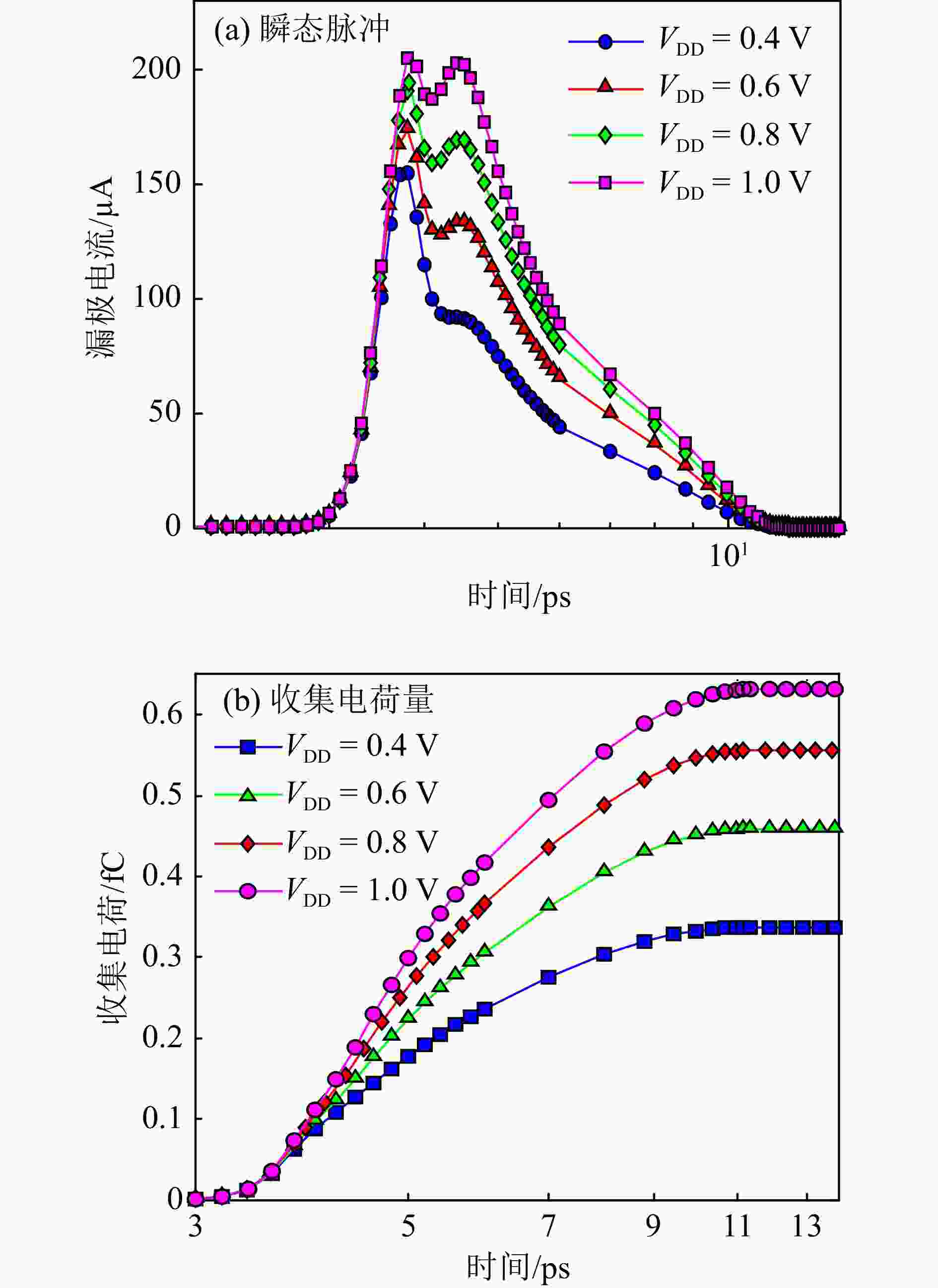

设置不同的偏压,得到4H-SiC FinFET器件的瞬态电流,如图2(a)所示。由图可见,随着偏压的增加,SET电流呈增加趋势,且双峰现象更加显著,这与SiC MOSFET在激光脉冲辐照时出现的多敏感位置[14]的结论一致,说明本文构建的SiC FinFET器件模型是可行的。下面来探讨瞬态电流出现多峰现象的原因。根据"漏斗"模型理论,高能粒子入射半导体材料时,在粒子入射路径附件产生大量的电子-空穴对,在漂移-扩散的作用下,形成瞬态电流。对于4H-SiC材料,瞬态电流的第一个峰值是由电子-空穴对在漂移的作用下形成的,在扩散的过程中,由于4H-SiC器件内部存在较强电场,快速收集电荷形成了第二个峰值[11]。当偏压较低(0.4 V)时,器件内部电场较弱,不足以快速收集电荷形成峰值;而当偏压升高时,较强的电场可快速收集电荷产生第二个峰值。图2(b)显示了不同偏压时收集电荷随入射时间的关系,可见,偏压越高,电荷收集率越大。

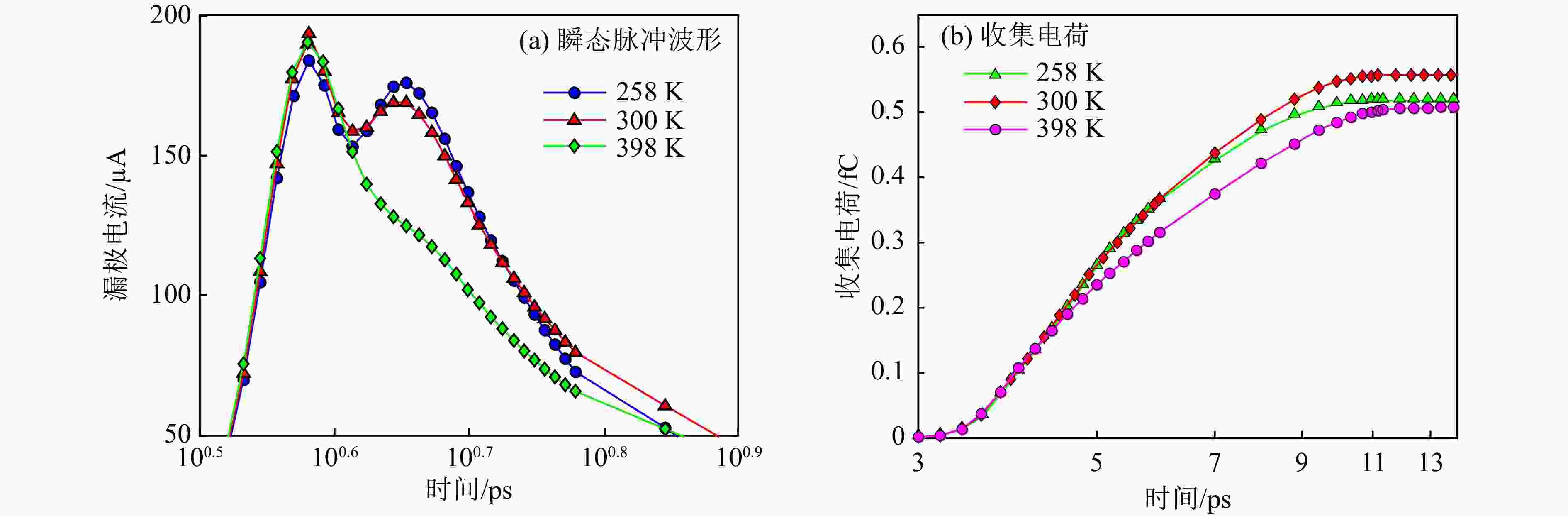

在TCAD中,通过设置受主陷阱特征温度系数来分析温度对SiC材料的影响,此系数取值为0.385。设置环境温度变化范围258~398 K,偏压0.8 V,得到不同温度下的瞬态脉冲电流及收集电荷如图3所示。与MOSFET不同,FinFET存在反温度效应,器件的驱动电流随着温度的升高而增加;器件的驱动电流越大,对累积电荷的消耗扩散越快[21],导致高能粒子入射产生的电子-空穴对数量减少,形成的SET减弱。所以,温度的升高,使FinFET器件的驱动电流增加,形成的SET减弱,从而提高器件的抗SET免疫性。因此,温度从258 K增加到398 K时,所产生的SET呈减弱趋势,且它们的电荷收集率基本接近,高温下的电荷收集率较低,故没有形成第二个峰值。

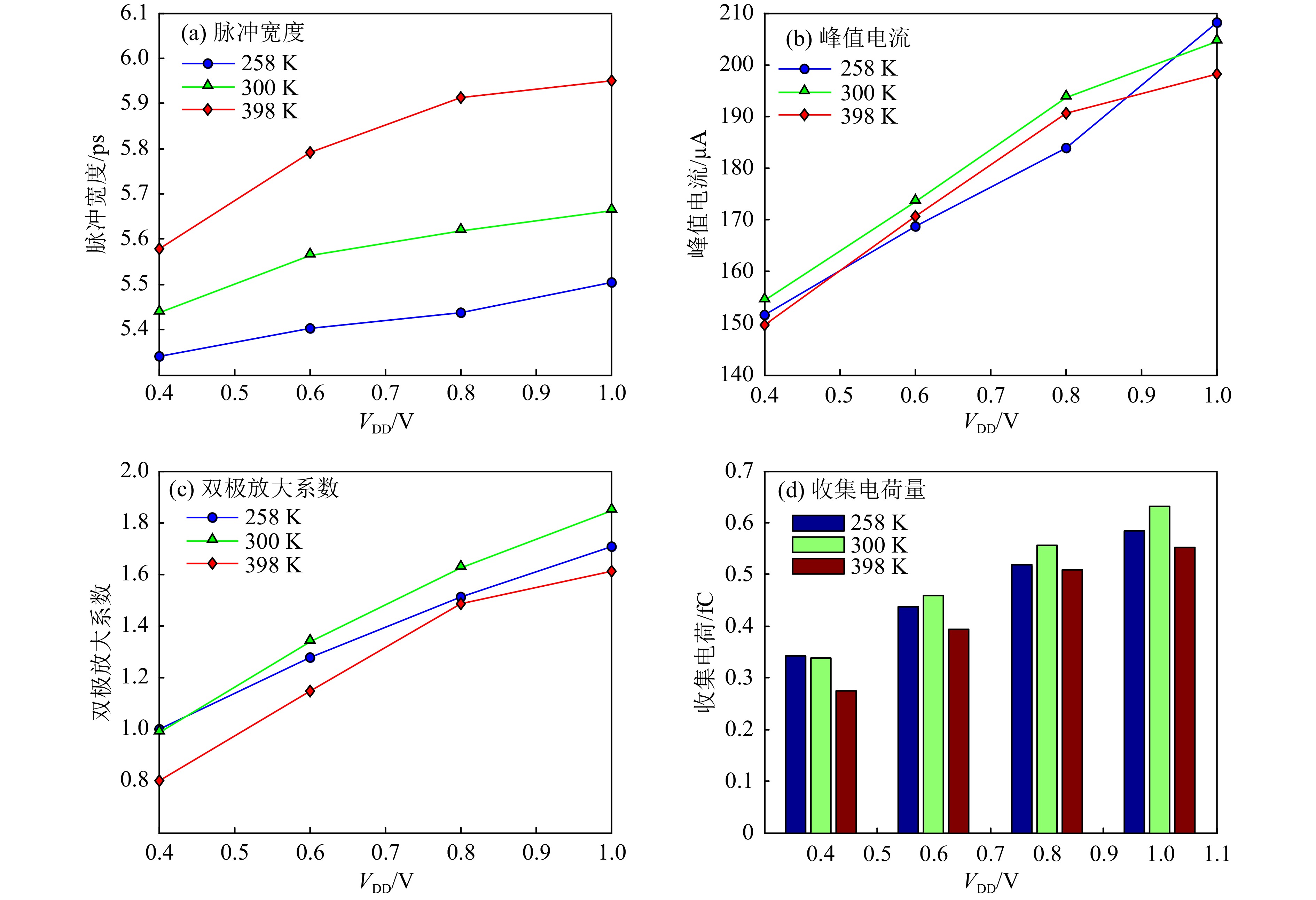

设置不同温度、不同偏压时,得到的器件的SET瞬态电流,结果如图4所示,其中,收集电荷Qc、脉冲宽度WSET及双极放大系数β分别定义[22-23]如下:

其中:ID(t) 是器件漏极得到的瞬态电流;Qd 是高能粒子入射器件过程中的累积电荷量。

由图4可见,随着偏压的增加,器件内部电场增强,器件对高能粒子电离产生的电子空穴对的收集能力增强,收集电荷的速率提高,导致产生较强的SET瞬态电流,这意味着偏压的增加会导致器件对SET的敏感性增强。对于温度300 K时,当偏压从0.4 V增加到1 V时,SET的峰值电流、脉冲宽度、收集电荷及双极放大系数分别相对增加32.39%, 4.15%, 87.26%和87.26%。由于偏压或温度对累积电荷量的影响几乎很小,因此,双极放大系数仅与收集电荷呈正相关。然而,随着温度的增加,由于费米能级的变化和带隙的减小,导致器件的阈值电压降低,进而使得器件的驱动电流增大,提高了器件对SET的免疫性,诱发了较弱的脉冲电流。因此,在增加温度和偏压的过程中,存在着电场增强引起快速收集电荷与驱动电流增大引起的抑制电荷收集的相互竞争现象。当温度较低(小于300 K)时,由偏压形成的电场占主导作用;当温度较高(大于300 K)时,由高温引起的驱动电流增加起主要作用。与温度300 K、偏压0.8 V的SET相比,峰值电流和收集电荷量在258 K, 0.4 V;258 K, 1.0 V;398 K, 0.4 V;398 K, 1.0 V时,相对变化分别是:−21.71%, −38.48%;7.43%, 5.08%;−22.77%, −50.83%;2.32%, −0.78%。可见,温度越高、偏压越小,产生的SET越弱;而温度越低、偏压越大,产生的SET越强。因此,针对空间辐射环境应用,可根据工作环境温度和所需器件电学性能的需求,在高温环境使偏压尽可能低或在偏压一定时调整工作温度,从而提高器件的抗辐射加固能力。

-

随着微纳电子技术的不断发展,涌现出了许多新材料、新结构、新工艺的器件。针对14 nm 4H-SiC FinFET器件,开展了温度和偏压对其SET的影响研究,从偏压引起的电场强度变化和温度引起的驱动电流变化两个方面,探讨了其作用机理。研究结果表明,偏压的增大会提高器件的SET敏感性;而温度的增加则会提高器件的抗SET免疫性。这些成果可为新型器件在空间辐射环境中的应用提供理论参考和技术支撑。

Investigation of Temperature and Bias Voltage Dependence of Single Event Transient in 4H-SiC FinFET

doi: 10.11804/NuclPhysRev.40.2022107

- Received Date: 2022-10-17

- Rev Recd Date: 2022-12-19

- Publish Date: 2023-09-20

-

Key words:

- single event transient /

- FinFET /

- temperature /

- bias voltage /

- 4H-SiC

Abstract: By TCAD, the model for single event transient(SET) in SOI 4H-SiC FinFET device at 14 nm technology node was simulated. With the temperature range from 258 to 398 K, the influence of the bias voltages on SET was analyzed and the potential mechanism was also discussed. The simulation results indicate that due to the temperature increase, the Femi energy of the device changes and the band gap reduces, which increases the driven current. Then it leads to improve the immunity to SET. However, because of the bias voltage increase, the inner electrical field in the device enhances, resulting in the rate of the charge collected increase, which increases the sensitivity to SET. Due to the competitive relationship between the impacts of the temperature and the bias voltage on SET, when the temperature is 398 K and the bias voltage is 0.4 V, the weakest SET is obtained. Compared with SET obtained at 300 K and 0.8 V, the weakest one is with the relative decrements of the current peak and the collected charge being 22.77%, 50.83%, respectively.

| Citation: | Baojun LIU, Liang QIAN, Xiaokuo YANG, Ping ZHOU. Investigation of Temperature and Bias Voltage Dependence of Single Event Transient in 4H-SiC FinFET[J]. Nuclear Physics Review, 2023, 40(3): 454-458. doi: 10.11804/NuclPhysRev.40.2022107 |

甘公网安备 62010202000723号

甘公网安备 62010202000723号 DownLoad:

DownLoad: